|

China Plastic Injection Mould Market Company

|

Gold Index: 12719

High Precision Injection Plastic Chair Mould Single or Multi Cavity Plastic Injection Tooling

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

<span style="background-co

1.Plastic Chair Mould Manufacturer

Name: Plastic Chair Mould

Cavity: 1*1 or as your requirement

Mould life: More than 100K shot

Material for cavity and core: 718H or equvialent

Runner: Hot runner or cold runner

Packing: Export wooden box

Shipping item: EXW or FOB shenzhen or CIF

1. High quality

2. Reasonable price

3. More than 10 years experience

SHENZHEN YONGHETAI TECHNOLOGY CO.,LTD We are professional in designing and manufacturing various kinds of mould.

We can also provide plastic injection service.

|

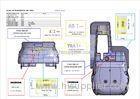

Molding Products Details |

|

|

Mould

Standard

|

HASCO,DME,MEUSBURGER,JIS,CHINA,LKM standard,etc. |

|

Mould Base

|

LKM ( Loadable Kernel Module ) |

|

Mould Material

|

P20,2316,2738,45C,50C,718H,738H,etc. |

|

The Composition of mold

|

Mould base + Mould Cavity |

|

Mould Life

|

300,000/500,000/1,000,000 shots,based on the materials |

|

Cavity quantity

|

Single or Multi ,or can be customized |

|

Cavity Insert,main core

|

DIN2312,2738,2344,718,S136,8407,NAK80,SKD61,H13,etc. |

|

Product Material

|

PMMA,PA,PBT,PA6/6+GF,ABS,POM,PC,PP,PET,TPE,PVC,HDPE,EVA,etc. |

|

Hardness of Steel

|

46-56HRC |

|

Gate

|

Cold runner/Synventive Hot runner/Yudo/DME/HASCO |

|

Surface request

|

Usual polish , high polish , grinder. |

2.How To Order Precision Injection Mould

3.With well-equipped tooling machines and highly responsible spirit, we can offer you cost-effective price and shorter delivery time.

4.How to pack the mould

1.Check mould component

2.Cleaning mould cavity/core and spread slushing oil on the mould

3.Cleaning mould surface and spread slushing oil on the mould surface

4.Put into the wooden case

5.How To Shipping

Shipping By Sea Or By Air

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

China Plastic Injection Mould Market Company [China (Mainland)]

Business Type:Manufacturer

City: Guangzhou

Province/State: Guangdong

Country/Region: China (Mainland)

You May Like:

Sitemap XML

About HiSupplier Help Center Customer Service Friend Links Site Map Archives

Browse by: China Suppliers - Hot Products - Products Directory - Offers Directory - Suppliers Directory - Buyers Directory

Language Option: العربية - Nederlands- Français- Deutsch- Italiano- 日本語- 한국의- Português- Pусский- Español